Understanding Flow Problems in Bulk Material Handling

When it comes to bulk material handling, smooth and consistent flow is critical. Whether you’re operating a dairy factory, a flour mill, a feed mill, a grain silo, or a food manufacturing plant, any interruption in material flow can lead to costly downtime, wasted product, and frustrated operators. Unfortunately, flow problems in hoppers, silos, and bins are common across many industries in New Zealand.

In this article, we’ll explore the most frequent flow issues—bridging, ratholing, and material hang-ups—why they occur, and how they impact production.

Common Flow Problems

1. Bridging

What is Bridging?

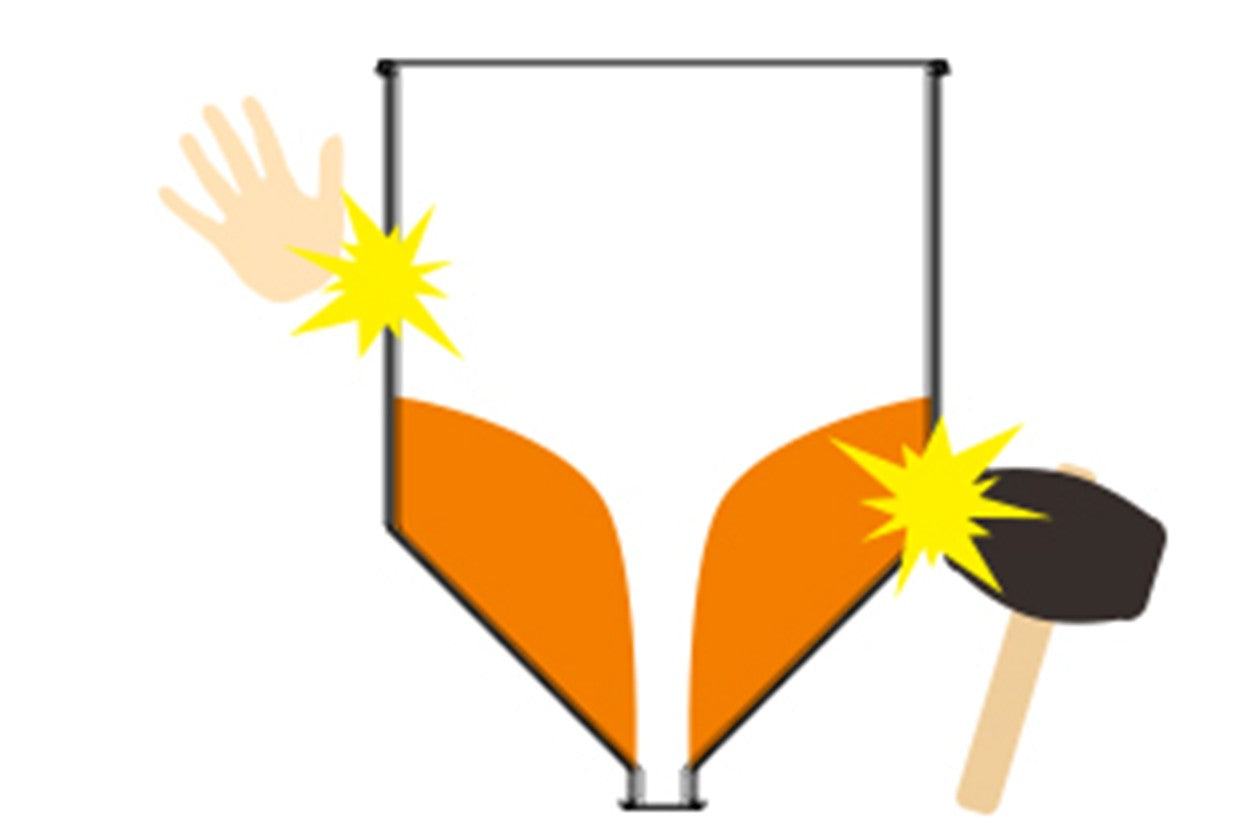

Bridging occurs when material forms an arch or bridge across the outlet of a hopper or silo, preventing further discharge. This creates a complete blockage at the outlet.

Why It Happens:

- Moisture content: Powders like milk or whey absorb moisture, making them cohesive.

- Particle size and shape: Fine powders or irregular particles interlock easily.

- Lack of vibration or movement: Without agitation, material compacts and locks in place.

Impact:

Operators often resort to manual intervention—hammering or poking—which is unsafe, time-consuming, and can damage equipment.

2. Ratholing

What is Ratholing?

Ratholing happens when material flows through a narrow channel above the outlet while the rest remains stagnant against the walls. This is common in tall silos storing flour or grain.

Why It Happens:

- Poor hopper design or insufficient wall angle.

- Cohesive powders sticking to walls.

- Inconsistent aeration or vibration.

Impact:

Ratholing reduces storage capacity, creates uneven flow, and often leads to complete blockages, causing unplanned shutdowns.

3. Material Hang-Ups

What are Material Hang-Ups?

Material hang-ups occur when product clings to the walls of the hopper or bin instead of flowing freely.

Why It Happens:

- Sticky or oily powders (e.g., dairy powders, cocoa).

- Residual static charge on surfaces.

- Inadequate surface finish or hopper design.

Impact:

Hang-ups are especially problematic in food and dairy industries where hygiene is critical—residual product can lead to contamination risks and extra cleaning time.

Why These Problems Matter

- Production Downtime: Every minute spent clearing blockages costs money.

- Product Waste: Manual clearing often damages product quality.

- Safety Risks: Hammering or entering confined spaces is dangerous.

- Compliance Issues: In NZ’s food and dairy sectors, contamination from stagnant material can lead to regulatory breaches.

NZ Industry Examples

- Dairy Processing Plants: Large-scale milk powder dryers and silos often face bridging and ratholing due to the fine, cohesive nature of dairy powders combined with seasonal humidity. These blockages can disrupt spray drying operations and delay packaging schedules.

- Flour Milling Operations: Flour is a highly aerated, fine powder that easily compacts in storage bins and hoppers. This makes ratholing and bridging common issues, especially in tall silos feeding high-speed production lines for bakery and food manufacturers.

- Fruit Ingredient Manufacturers: Producers of fruit-based inclusions and pastes deal with sticky, high-moisture products that tend to cling to hopper walls. This creates material hang-ups and inconsistent flow during batching and mixing processes.

- Animal Feed Mills: Pelletised feed and mineral blocks often contain molasses or fats, which increase stickiness and cause bridging in feed bins. Seasonal temperature changes can also lead to condensation inside silos, worsening the problem.

- Breakfast Cereal and Snack Producers: Dry ingredients like oats, grains, and sugar blends can segregate or compact during storage, leading to ratholing in ingredient hoppers. This slows down continuous production lines and increases manual intervention.

- Food and Beverage Manufacturers: Plants handling powdered ingredients for beverages or confectionery face similar challenges—fine powders like cocoa or milk derivatives can form bridges or cling to hopper walls, impacting dosing accuracy and hygiene compliance.

What’s Next? Practical Solutions for Flow Problems

To achieve consistent flow you may need to employ some assistance by using a flow-aid such as an electric vibrating shaker motor, a pneumatic impactor or a pneumatic vibrator.

Italvibras MVSI Electric Vibrators

For continuous, heavy-duty applications, Italvibras MVSI foot-mounted electric vibrators deliver consistent, powerful vibration to keep material moving. They’re ideal for large silos and hoppers in flour mills, dairy plants, and grain storage facilities where constant flow is critical. With robust construction and a wide range of sizes, MVSI units are designed for reliability in demanding environments. Also available in micro options and stainless steel.

Netter Vibration Pneumatic Solutions (NTS, NCT, PKL, NTK)

When you need targeted or intermittent vibration, Netter’s pneumatic range offers flexibility and precision:

- NTS Linear Vibrators provide strong linear force for compacting or loosening material.

- NCT Turbine Vibrators deliver high-frequency vibration for fine powders like milk or flour.

- PKL Knocker Vibrators are perfect for dislodging stubborn build-up on hopper walls without damaging the structure.

- NTK Oscillating Vibrators combine impact and vibration, making them ideal for sticky or cohesive materials that resist flow.

These solutions are supplied by RR Fisher and widely used in NZ food and beverage plants, ingredient processing, and feed manufacturing where hygiene and efficiency are top priorities.