When a drive belt fails, downtime costs start ticking immediately. Every maintenance manager knows the pressure of sourcing the right size belt, fitting it into a tight space, and getting machinery back online as fast as possible.

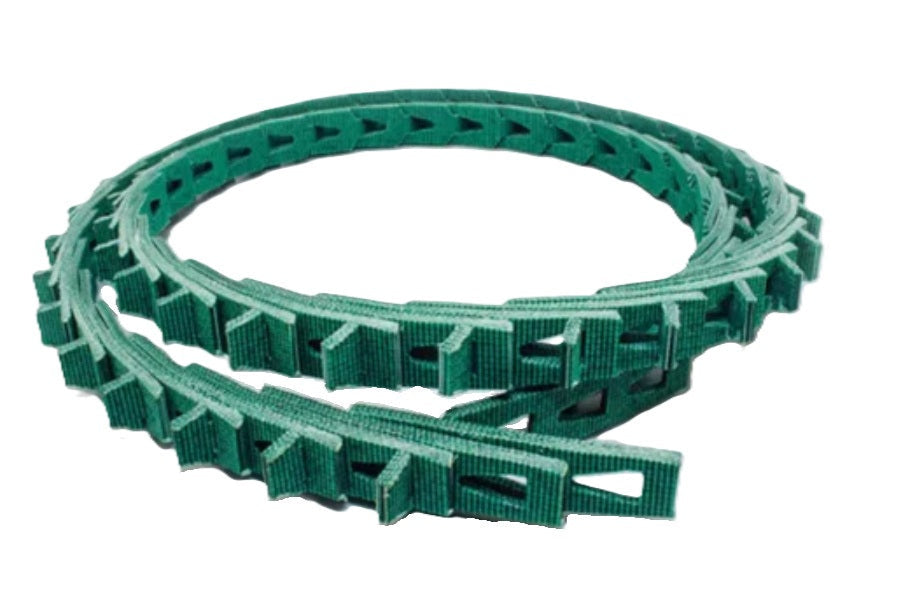

That’s exactly where Accu-Link Adjustable Link Belting shines. Designed as a versatile alternative to conventional rubber V-belts, Accu-Link belts offer fast installation, easy repairs, and the ability to assemble any length on the spot.

Why Choose Accu-Link Belting?

- Emergency-ready: Always have the “right belt size” on hand, no matter the drive.

- No dismantling required: Wrap it around pulleys like a bicycle chain, then link by hand.

- Durable & strong: Polyester fabric reinforcement and polyurethane elastomer mean resistance to oil, grease, abrasion, and wide temperature ranges (-25 °C to +80 °C).

- Low vibration: Smooth operation and less wear on pulleys.

- Cost-saving: Stock rolls instead of dozens of belt sizes,

What is Accu-Link Adjustable Link Belting?

“Adjustable link belting” refers to conveyor or drive belts made in linked segments. Instead of being one continuous loop or a solid flat sheet, the belt is made of multiple rigid or semi-rigid links (or modules) that lock together. The Accu-Link line offers:

- Multiple belt sections/types (e.g. M (Z), A, B, C sections) to suit different loads, speeds, and pulley geometries.

- Meter-sized belts, so you can cut to length, adjust the pitch, or replace sections rather than the whole belt.

Step-by-Step: How to Assemble Accu-Link Belts

- Hold the belt with the tabs pointing outward.

- Place the two belt ends through two links at once.

- Flex the belt and insert the first tab through the end link, twisting slightly with your thumb.

- Insert the second tab the same way, then make sure tabs return to their crosswise position across the belt.

- Reverse the belt so tabs run inside.

That’s it — no tools, no cord damage, no dismantling of equipment.

Step-by-Step: How to Disassemble Accu-Link Belts

- Hold the belt upside down and bend it back as far as possible.

- Twist one tab 90° so it lines up with the slot.

- Pull the end link over the tab and rotate the belt end free.

- Pull the belt through the two links.

Simple, fast, and safe — perfect for on-site repairs.

Where Accu-Link Belts Deliver the Most Value

- Emergency repairs: Get a machine back online in minutes instead of hours.

- Preventative maintenance: Keep rolls in stock and reduce unplanned downtime.

- Problem drives: Great for misaligned pulleys or hard-to-access machinery.

- Service vehicles: A few rolls cover hundreds of applications, saving space and cost.

The RR Fisher Advantage

We stock Accu-Link Adjustable Link Belts in popular A, B, C, and M (Z) sections, ready to ship. Whether you need an emergency spare, or want to simplify your maintenance strategy, we can help you select the right solution.