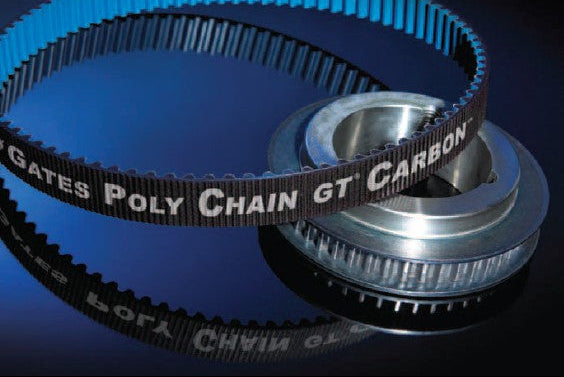

In the world of industrial power transmission, few innovations have made as significant an impact as Gates’ Poly Chain® GT® Carbon™ belts. These synchronous belts have revolutionized drive systems across industries—from food processing to mining—by offering unmatched strength, efficiency, and maintenance-free operation and RR Fisher is pleased to stock a large range.

A Brief History of Poly Chain® Technology

Gates has been at the forefront of belt technology since the 1940s, starting with the PowerGrip® classical pitch belt. Over the decades, synchronous belts evolved through several generations:

- 1970s: Introduction of HTD (High Torque Drive) belts.

- 1980s: Launch of the first Poly Chain® GT® belts with aramid (Kevlar) cords.

- 2006: Debut of Poly Chain® GT® Carbon™, featuring carbon fiber tensile cords for superior strength and flexibility.

This progression reflects Gates’ commitment to materials science and engineering excellence, culminating in a belt that outperforms roller chains in nearly every metric.

Product Range and Specifications

Poly Chain® GT® Carbon™ belts are available in:

- 8mm and 14mm pitch options.

- Widths ranging from 12mm to 68mm, with extended lengths up to 20,000mm for long center distance applications.

- Compatible with Poly Chain® GT®2 sprockets, including stainless steel variants for washdown environments.

They’re also available in long-length linear formats for conveying and positioning systems, and Volt™ antistatic versions for ATEX environments.

What Makes Poly Chain® GT® Carbon™ Belts Superior?

These belts stand out due to their advanced construction:

- Carbon fibre tensile cords: Deliver high strength, minimal stretch, and excellent fatigue resistance.

- Polyurethane body: Chemically resistant and durable against oil, moisture, and abrasion.

- Nylon tooth facing: Reduces friction and eliminates the need for lubrication.

- Modified curvilinear tooth profile: Enhances load distribution and reduces backlash.

Performance Highlights

- 400% greater capacity than HTD belts.

- 30% higher power ratings than previous Poly Chain® generations.

- 99% efficiency for the life of the drive.

- Operates in extreme temperatures: -54°C to +85°C.

- Maintenance-free: No lubrication, no re-tensioning, no stretch.

Advantages Over Roller Chain Drives

Switching from roller chain to Poly Chain® GT® Carbon™ belts offers tangible benefits:

- Up to 3X longer belt life and 10X longer sprocket life.

- 97% weight reduction, improving ergonomics and reducing overhung loads.

- Zero maintenance—no oil baths, no link removal, no downtime.

- Cleaner operation—ideal for food, beverage, and washdown environments.

- Improved safety—no pinch points, no fire risk from oil lubrication.

Applications Across Industries

Poly Chain® GT® Carbon™ belts are used in:

- Food & beverage: Hygienic, rust-free, and washdown-ready.

- Mining & construction: High torque, shock-resistant.

- Textile, pulp & paper: Long center distances and precise positioning.

- Agriculture & forestry: Durable in harsh outdoor conditions.

Conclusion: The Drive of the Future

Conclusion: The Drive of the Future

Gates Poly Chain® GT® Carbon™ belts are more than just a replacement for roller chains—they represent a leap forward in power transmission. With their high efficiency, low maintenance, and robust design, they’re the ideal solution for modern industrial applications.

At RR Fisher, we trust Gates Poly Chain® GT® Carbon™ belts for demanding environments where reliability and performance matter. Whether it's food processing, materials handling, or heavy industry, these belts deliver consistent results with minimal downtime.

While Gates belts are widely recognized for their performance and reliability, other manufacturers like Optibelt offer similar high-performance solutions such as the Delta Chain Carbon. These belts also feature carbon tensile cords and polyurethane construction, and are designed to be compatible with Gates’ pulley profiles. However, Gates continues to lead the market with broader availability, proven efficiency, and a more extensive product ecosystem.

Whether you're designing a new system or upgrading an existing one, Poly Chain® GT® Carbon™ belts from RR Fisher offer the performance, reliability, and cost savings that today’s industries demand.

.