Banded V-Belts vs Single V-Belts: Which is better for the application?

In industrial settings across New Zealand, V-belts are a staple in power transmission. While banded V-belts offer clear advantages in certain applications, single V-belts remain the more versatile and most commonly stocked option. Understanding when to use each can save time, reduce downtime, and optimise the stock you hold onsite or the options you have in a breakdown situation.

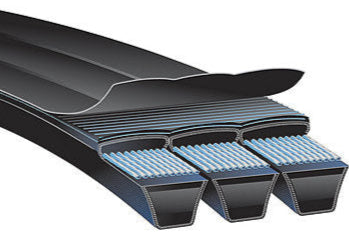

🧩 What Are Banded V-Belts?

Banded V-belts are essentially multiple single V-belts joined together by a continuous tie-band across the back. This design increases lateral rigidity, helping the belt resist whip, vibration, and misalignment—especially in systems with:

- Long centre distances

- Pulsating or shock loads

- High torque requirements

They simplify installation and tensioning compared to multiple singles

✅ Advantages of Banded V-Belts

-

Improved Load Sharing

All belts in a banded set are the same length and tension, ensuring equal load distribution -

Reduced Belt Whip and Slippage

The tie-band prevents individual belts from flipping or slipping off under load -

Better Alignment

Joined belts stay aligned across pulleys, reducing wear and vibration -

Longer Service Life

Even wear and reduced movement extend belt life and reduce maintenance -

Ideal for Harsh Conditions

Banded belts perform well in dusty, high-temp, or high-load environments like mining, agriculture, and heavy manufacturing.

⚠️ Limitations of Banded V-Belts

Despite their performance benefits, banded belts come with trade-offs:

-

Less Stock Flexibility

If you have a 3-band and a 5-band belt of the same size, they’re not interchangeable. But five single belts could serve either application. -

Longer Lead Times

Banded belts are often not stocked locally and may require special ordering -

Higher Upfront Cost

While they reduce downtime, banded belts can be more expensive initially

📦 Why Single V-Belts Are Still King in as spare parts.

For many maintenance teams, single belts are easier to stock and source. They offer:

- Greater versatility — one belt can fit multiple machines.

- Simpler inventory management — fewer SKUs to track.

- Faster replacements — readily available from most suppliers.

In fact, stocking matched sets of single belts allows you to build your own “banded” solution when needed, without being locked into a specific configuration.

🛠️ When to Use Each Type

Use Banded V-Belts for:

- High vibration or shock loads

- Long centre distances

- High torque, heavy-duty applications

Use Single V-Belts for:

- General-purpose, light-duty setups

- Flexible stocking strategies

- Machines that share belt sizes but differ in band count (e.g., 3-band vs 5-band)

🔄 Stocking Strategy Tip

If you have machines using both 3-band and 5-band belts of the same profile and length, consider stocking five single belts instead. This gives you the flexibility to service either machine, reducing inventory costs and improving responsiveness.

🧠 Summary

Banded V-belts are a powerful solution for demanding applications—but they’re not always the most practical choice for stocking and maintenance. By understanding the strengths and limitations of each type, you can make smarter decisions that balance performance with flexibility. Call the RR Fisher team on 0800 235 877, email on sales@rrfisher.co.nz or browse the range here.